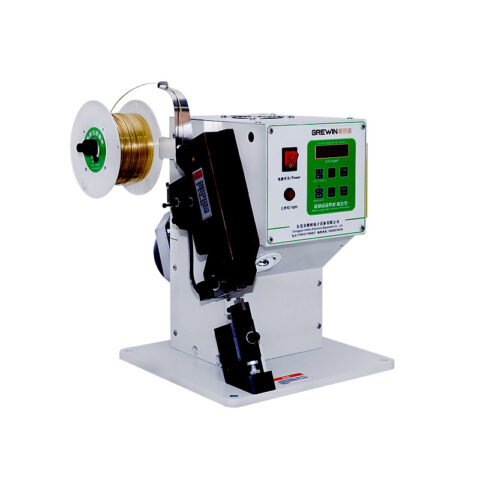

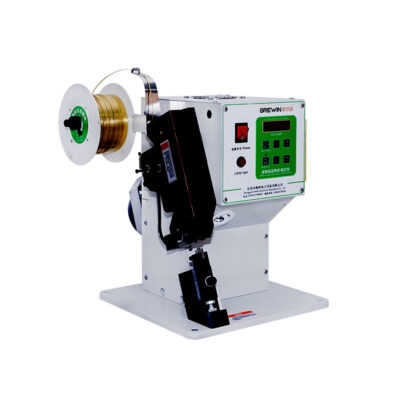

Automatic Wire Splice Machine

Automatic Wire Splice Machine

Copper Band Splicing Machine

Wire Splicing Machine

Wire Splicing Machine

Automatic Wire Splice Machine Application Scope:

Output: 1.8T

Product characteristics

• Copper belt wiring machine upgrade products, simplify the internal mechanical parts, reduce mechanical parts wear and replacement!

• The main engine is driven by variable frequency motor, without the mechanical action delay and failure of the traditional clutch, large torque, small vibration, high stability, providing a super quiet working environment.

• No flywheel design, the motor is at rest in the standby state, and only rotates when working, and energy is not wasted on the rotating flywheel.

• Punch up and down buttons are added to the key panel of the machine, no need to use a wrench to shake the spindle when debugging the mold.

• The working times of the machine can be adjusted in the range of 1-20 times. The working interval can be adjusted in the range of 0-20min

Automatic Wire Splice Machine Features:

Working voltage: 220V (V)

Pressure output: 3000 (kgs)

Dimensions: 400-400-400 (mm)

Weight: 50 (kg)

Output: 3T

Feeding mode: new pneumatic type

Max feeding: 22MM

Applicable copper belt: 1-6MM

Applicable copper strip thickness: 0.25-0.5

Feeding method: step feeding

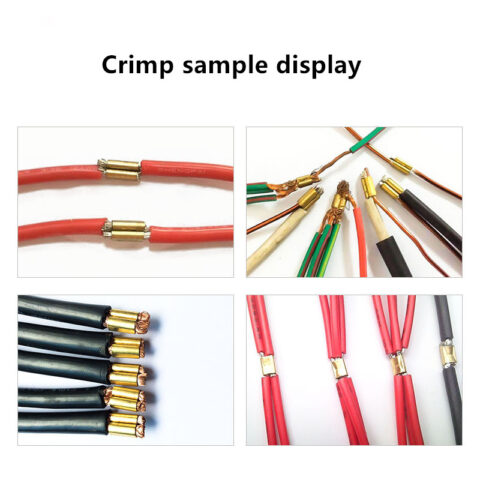

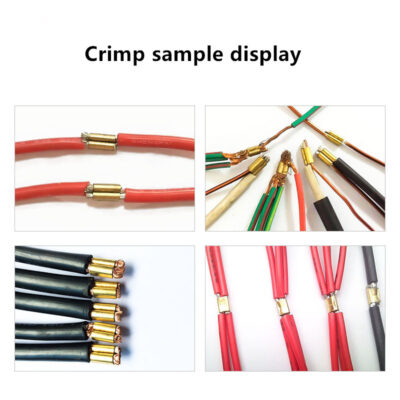

Uses: wire riveting, electronic components and wire connection