Wire Cutting Stripping Twisting Tinning Machine

2. Can processing 1-8 wires at the same time;

3. Also can processing flat wire/cable(wire separate, cutting, stripping and tinning);

4. If you need custom made, we have our professional engineer team support you;

5. Over 20 years experience, offer you factory price and good after-sales service;

6. Every machine parts we upgrade year by year, with high quality and long working life

wire cut strip twist tinning machine

wire cutting stripping tinning machine

Automatic Wire Stripping Twisting and Tin Soldering Machine

Full automatic wire stripping tinning machine

wire cutting tinning machine

Machine working video:

Wire Cutting Stripping Twisting Tinning Machine description:

Wire Cutting Stripping Twisting Tinning Machine is the company’s well-designed automated machines are mainly characterized by wire stripping and

Full-automatic machine developed for the purpose of dipping tin.

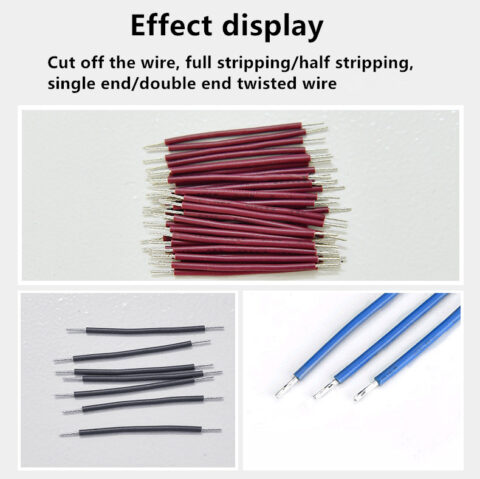

1. The machine is powerful and can be double-headed with tin, single-headed with wire Short-term peeling and tin;

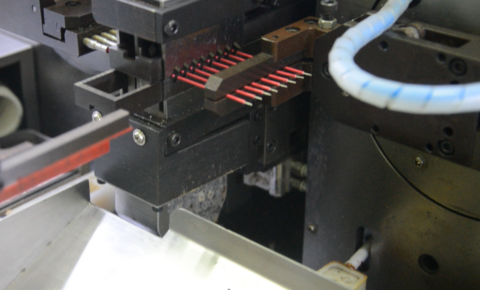

2. The front part of the machine uses two sets of wire feeding wheels. When the machine is producing eight wires at the same time,

It can control the length of the wire feeding more stably. The rear part adopts the cylinder braking mechanism. Perform back-end skinning;

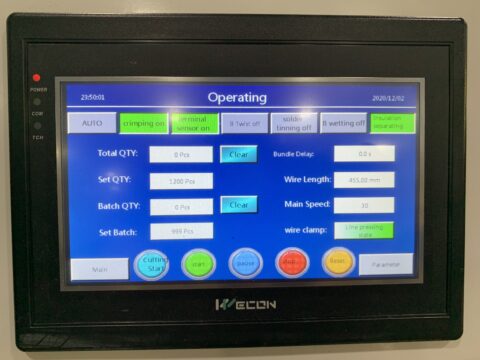

3. The main parts of this machine are driven by Japanese Servo stepping motor and Panasonic PLC control system, which are simple in operation, accurate in positioning, high in accuracy and long in service life;

Wire Cutting Stripping Twisting Tinning Machine Specifications:

Function: Wire cutting stripping twisting and tinning

Wire specifications: UL1007AWG # 16 ~ AWG # 32

Processing length: 8mm ~ 9999mm (3mm or more can be twisted)

Processing accuracy: ± 0.1mm

Peeling length: front 10mm, rear 10mm

Production efficiency: 15000-18000PCS / hour (8mm ~ 100mm)

Power supply: AC220V 60HZ / 50HZ single phase

Compressed air: 0.5Mpa ~ 0.7Mpa

Machine size: length 1120mm × width 730mm × height 1200mm

Weight: 289KG

Processing 1-8 wires at the same time

Fully Automatic Wire Cutting Stripping Crimping & Tinning Machine

Fully Automatic Wire Stripping Crimping Tinning and Twin Pair Twisting Machine

Fully Automatic Wire Stripping Twisting Crimping and Soldering Machine

Full Automatic Wire Stripping Crimping and Tin Soldering Machine

Ribbon Cable Crimping and Soldering Machine, Automatic Ribbon Cable Stripping and Crimping Machine

Automatic Wire Stripping Twisting Tinning and Crimping Machine

Multi-core Cable Stripping and Soldering Machine

Wire Stripping Twisting and Soldering Machine

Automatic Wire Tinning/Stripping/Twisting/Soldering Machine